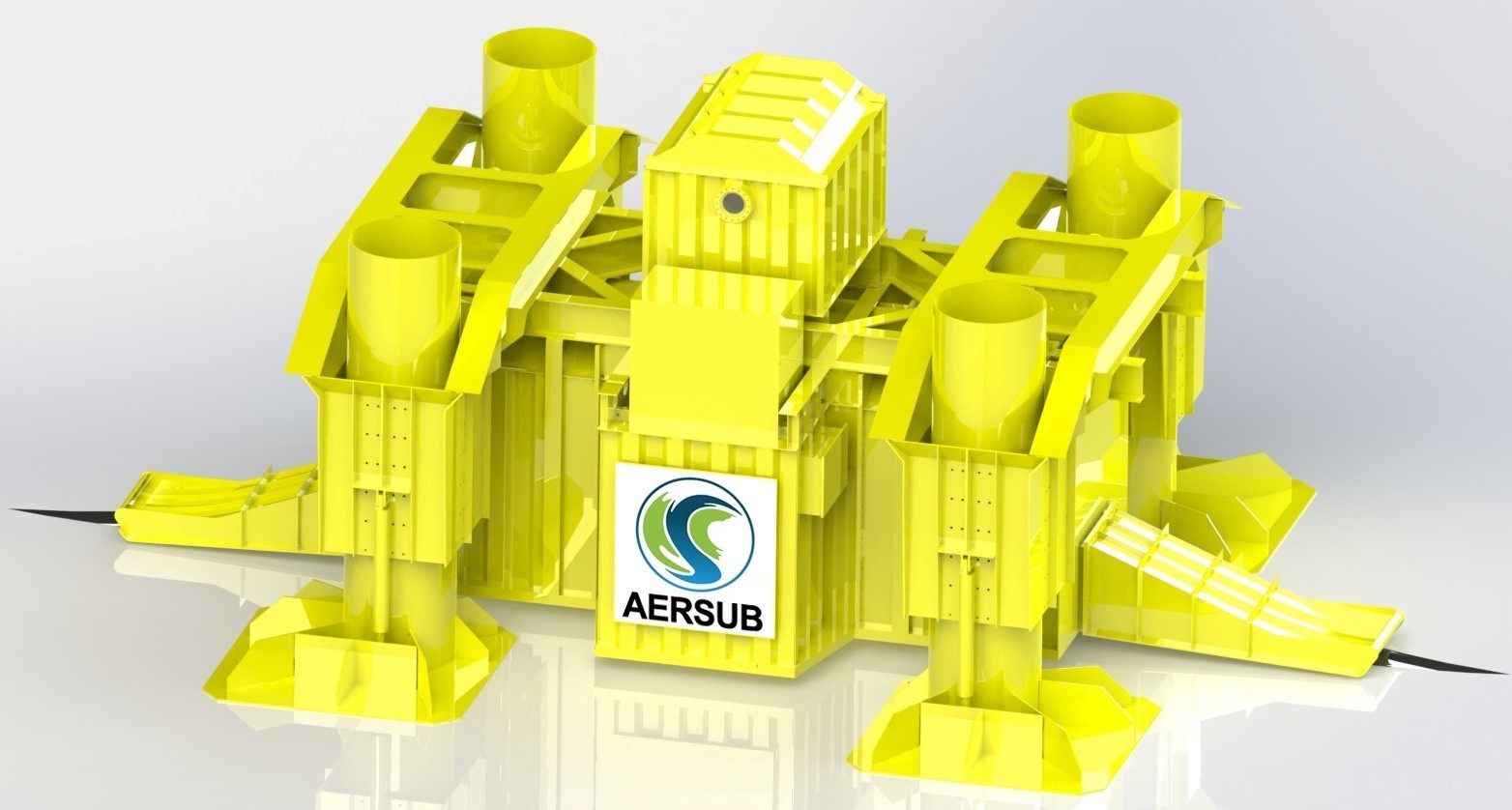

AERSUB - Hyperbaric Subsea Cable Repair Habitat

Overview

Irish Sea Contractors (ISC) AERSUB System is an innovative, first of its kind subsea hyperbaric cable repair habitat aimed primarily at subsea cable & control umbilical repair. After ISC was approved for the design and process patent, they began construction works on a prototype unit. The time from initial design to first system submersion trials were achieved in an impressive 12 months. Upon completion of the first “proof of concept” wet trials, ISC wanted to further streamline the operation and discussed options with Namaka Subsea regarding a technical inspection in line with industry requirements and best practice.

Approach

As AERSUB is the first of its kind, there is no specific guidance in which to carry out a technical inspection of the system against regulations and industry best practice. However, ISC was made aware that the team here at Namaka Subsea had recently completed development of our subsea hyperbaric welding habitat auditing tool, taking guidance from IMCA and NORSOK, and had very successfully completed our first inspection of a subsea hyperbaric welding habitat for Subsea 7.

Results

After the initial discussion with ISC regarding AERSUB, we quickly realised that our subsea habitat system auditing process would be the ideal solution to their technical inspection requirements. From this initial meeting, the project work scope has now extended requiring further Namaka Subsea input, seeing the project evolve into the following phases.

- Phase One

The initial technical inspection was carried out during the process of the system build, identifying various points to be considered, especially; due to the system being an original design. We worked closely with ISC to rectify these issues and further tailor our subsea hyperbaric welding habitat system auditing process to suit the needs of this newly designed habitat, while still maintaining industry requirements and best practices with guidance taken from IMCA and NORSOK each step of the way. The technical inspection identified certain failure modes of the design whereby ISC increased our scope of works (Phase Two).

- Phase Two:

Namaka Subsea carried out a Failure Modes Effects and Criticality Analysis (FMECA) on AERSUB to assess the system failure modes and determine any potential points of failure with the design. Due to the system being the first of its kind, this process, identified potential issues; the main one being in relation to the electrical design and layout within the subsea habitat and the control room. It was identified that the location of the electrical control systems was not suitable for this type of installation. Initially we discussed reconfiguring the existing electrical control systems, however, as this process progressed it became apparent that the most practical way to rectify the issues was a redesign of the system, relocating control to topside.

- Phase Three:

This phase of the project called upon the technical abilities of our team here at Namaka Subsea to redesign the electrical layout for the subsea habitat and control room including some components of the main supply umbilical. This process saw many hours of design breakdown, analysis, calculations, and CAD drawings to determine the safest and most cost-effective way to achieve the re-design for our client. The process was more time consuming than first anticipated but provided the safest and most cost-effective solution for our client. Namaka Subsea created a series of technical drawings, parts lists, supporting technical database and registers to provide ISC with a brand-new road map for the electrical design, which can now be easily replicated for any future projects of the same nature.

- Phase Four:

During this phase of the project, Namaka Subsea was engaged to assist in the development of the operational documentation necessary for ISC’s innovative AERSUB system, ensuring it is compliant with industry/regulatory bodies, IMCA and NORSOK guidelines. This work scope included design validation (including some slight modifications) to the environmental regeneration system, habitat heating (including thermal balance verification), various supporting operating/maintenance manuals and procedures. It was also noted during this process that there was currently no way of tracking the maintenance requirements of AERSUB. As an existing DiveCERT client (a product of Namaka Subsea) ISC enquired if we could develop the system to suit the maintenance requirements. At this time however, we were currently developing our new cloud based Namaka Asset Management System (NAMS). Comparing both systems, we felt the best way forward was to develop NAMS instead of DiveCERT. One of the reasons we felt this was the better option was due to all the new functionality we have included in the new system that ISC would be able to take full advantage of. An example of this is having the ability to receive regular updates on the system status and maintenance requirement straight to inbox from any global location.

In Summary

The initial 5-day inspection for which Namaka Subsea was engaged for, subsequently increased to over 4 months, delivering on various aspects of this exciting project. During this time, we have successfully helped ISC implement various cost and time saving processes and provided them guidance, solutions, and support at each step of the way. These continuing engagements from ISC demonstrate our strong client focus and the confidence they have in our delivery. For the team here at Namaka Subsea, it has been an absolute pleasure to work with ISC to implement these changes and witness first-hand the evolution of the subsea hyperbaric cable repair habitat. We know that the product ISC now has is truly a global innovative solution when it comes to subsea cable repair. Overall, this has been a challenging project at times, but also a very rewarding one and Namaka Subsea look forward to an ongoing relationship with ISC.

Can we help you with your next project?

get in touch and see how we can assist